Corrosion Control in Datacentres

Fight the invisible

When you think of microelectronics, you think of vulnerable products. Optical equipment, datacentres, clean rooms, semiconductor manufacturing. One tiny dust particle can already cause a lot of harm. Keeping processes optimal and preventing contamination requires specific solutions. CF Industrial's filter media effectively remove gases and save energy costs.

Datacentres spring up like mushrooms these days all around the world. The big data cloud keeps growing and in order to have enough capacity to store this data, datacentres are crucial for companies and its customers. To make sure the data is stored safely, datacentres rely on the sensitive high tech electronical equipment. Preventive corrosion control is therefore of most importance. Adsorption filter media is a great solution for preventing these types of damages.

Where do these corrosive gasses come from?

As can be seen from the image on the left side, datacentres are often surrounded by other industrial plants. These industrial plants can cause the air to be polluted with corrosive gasses. Also in non-industrial environments pollution can occur. For example, agricultural companies and especially livestock farms, are source of gasses like ammonia, which can cause corrosion to sensitive electronical parts.

How to detect the problem?

The presence of these corrosive gasses can be detected easily by execution of a “Coupon Test”. These can be used to check the air quality in the current situation, and after installation to determine the effectiveness of the HVAC system. Also for existing systems a coupon test can be executed. The test makes use of a copper and silver test strip. These are placed for at least 30 days. The levels of corrosion are determined and an official report is put together according to the industry standard ISA-71.04-201

What is the solution?

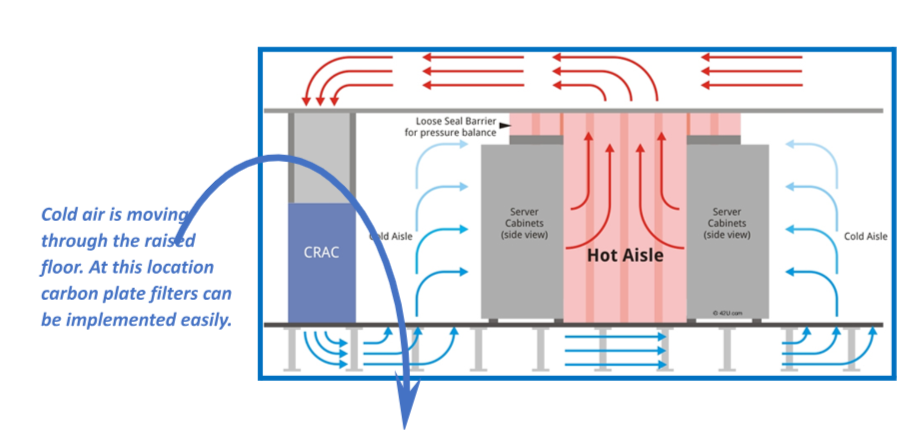

The solution which is most often implemented for datacentres is using the principle of recirculation of air. Datacentres generally have raised floors in where cool air from the AC unit is coming through in order to cool the equipment in the datacentre. In these existing situations carbon plate filters can be incorporated into the raised floor of the datacentre. This has a benefit that the filters can be placed in an efficient way where they will not take up a lot of extra space. In this way clean air is provided through this filtration step in the raised floor.

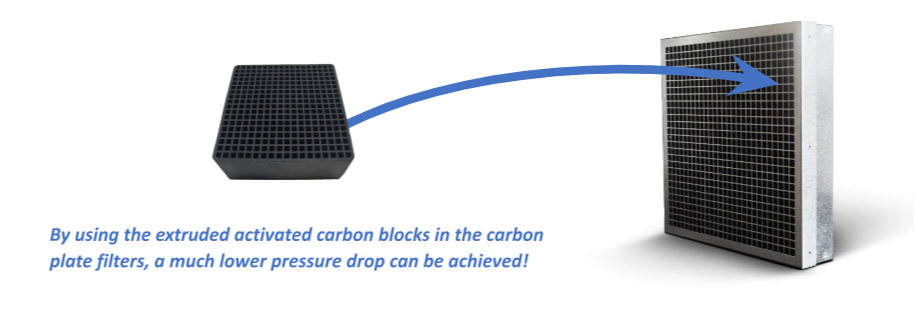

Dealing with the high pressure drop

The main deficit of a panel filter using loose fill adsorption filter media is that these panels generate a relatively high pressure drop in comparison to the efficiency of the filter. With datacentres having to take responsibility for their energy consumption and carbon footprint, a higher pressure drop can be very costly for the operational costs. The contact time of the filter is low due to the air speed in combination with the thickness of the filter bed, but the pressure drop is extremely high in comparison to cylindrical cartridges for example. A solution for this could be the usage of extruded honeycomb activated carbon blocks, instead of the loose fill media. These blocks are completely made out of activated carbon, and have a very low pressure drop. This reduces also the contact time even further, but since we are implementing a recirculation system the air is going through the filter multiple times, which makes sure that all of the corrosive gasses are taken out in the end.