Odour control in Professional Kitchens

CF Industrial is active in almost all sectors within the food and beverage industry, especially when it comes to odours and potential nuisance. From drinks and dairy products to meat processing and from fruit and vegetables to sweets and candies. Our solutions help food processing companies protect people, processes and products.

A proper operating air ventilation system is of essential importance in order to assure a clean, safe and sustainable working environment. For the people working in the kitchen and the people living in the direct area. A professional approach in the design and implementation of such ventilation systems ensures high performance, high

durability and high reliability.

What is important for an effective kitchen ventilation system?

As with normal odour control, the prefiltration of the air is very important for an optimal result. A proper grease filter is also important for safety in the kitchen. It prevents the duct work from becoming clogged with fat, which can cause fires to spread. No fat or moisture should be in the air after these filters or else the carbon filters will be wet or covered in fat, which results in the odour filter not functioning as well.

Special mixes of media to assure odour control in different situations.

Not every type of odour can be removed from an airstream using the regular coal-based activated carbon. For example the specific odour of fish, which results from an alkaline type gas. These odours are best removed using an impregnated carbon. This is an activated carbon which has been treated with a chemical impregnant. This impregnant reacts with the gas that causes the odour, and the odour is thereby removed and adsorbed by the activated carbon. A mix of different types of activated carbon can be designed in order to get the optimal working odour filter solution for your kitchen.

What is the solution?

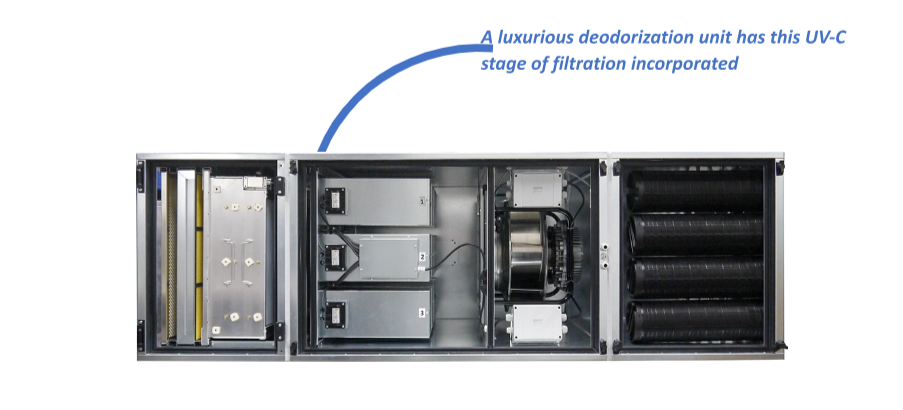

As mentioned, the solution begins with a good quality hood where proper metal filters are integrated into. Next up is the air filter unit. This one is most often placed on top of the roof of the building. An example is given in the image below on the left side. These cabinets can be equipped with different stages of air filtration. The most common version is a two stage filter cabinet with a stage of particle filtration using a pocket filter. The second stage and final stage is always a stage of activated carbon filters.

The more luxurious deodorization units incorporate an extra filtration stage. This is a UV-C stage of filtration which breaks down the fat and odour molecules resulting in a higher efficiency on the activated carbon filter. The remaining gasses which result from this process of UV-C can be removed by the final stage of activated carbon filter cartridges. Below an example of such a luxurious system is presented.