With large oil free compressors, which are implemented in the industry for generation of compressed air, the quality of air going in is very important. The fact that poor air quality can shorten the lifetime of a compressor massively is often overlooked. Corrosion can play a big role in shortening this lifetime. Due to the presence of acid or base gasses in the incoming airstream, interior parts of the compressor can be affected by these gasses and start to corrode. Corrosion affects different parts of the compressor. The impellor is one sensitive place where corrosion can do real damage. This needs to be perfectly balanced, and due to corrosion this can start to vibrate until the bearings give in and the compressor breaks down. Not only does the compressor suffer from corrosion, also the components behind a compressor are at risk.

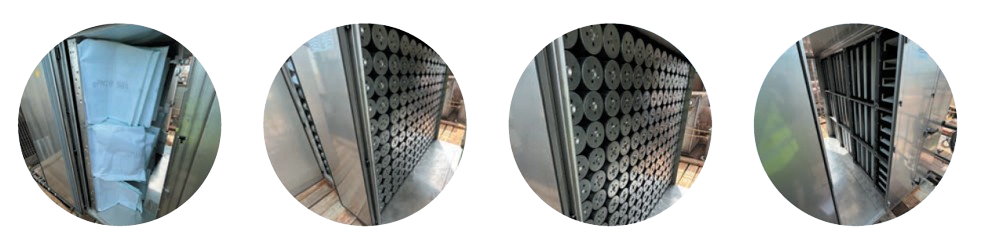

| Airflow (m³/h) | Type | Internal size (mm) | Number of cylinders | Qty of Activated Carbon (kg) |

|---|---|---|---|---|

| 2800 | 1261 | 1220 x 610 | 32 | 74 |

| 4300 | 1291 | 1220 x 915 | 48 | 110 |

| 5700 | 1212 | 1220 x 1220 | 64 | 147 |

| 7200 | 1512 | 1525 x 1220 | 80 | 184 |

| 8600 | 1812 | 1830 x 1220 | 96 | 221 |

| 10000 | 2112 | 2135 x 1220 | 112 | 258 |

| 11500 | 2412 | 2440 x 1220 | 128 | 294 |

| 12900 | 1818 | 1830 x 1830 | 144 | 331 |

| 15000 | 2118 | 2135 x 1830 | 168 | 386 |